|

|||||||||||||||||||||||||||||||

| This super wide angle lens was

released in the same year the Nikon F was introduced. It firmly established

Nikon as the market leader at the time, because no other Japanese manufacturers

could offer anything as wide! The rear of this lens

protudes so much into the mirror box that there is not enough clearance

for the mirror to swing up and down. As a result, the mirror has to be locked

in the "UP" position all the time whenever this lens is in use. This problem

for ultra wide angle lens was later on solved by the introdution of retrofocus

design which increases the back focus distance and reduces vignetting. A

dedicated view finder mounted above the film rewind crank is supplied for

viewing. The lens is renowned for its sharpness and minimal distortion,

making it particularly suitable for architecture or interior shooting. |

|||||||||||||||||||||||||||||||

|

Left: The lens has no automatic aperture. It does not really need one, because viewing and TTL metering through the camera's viewfinder are no longer possible with the mirror in the UP position anyway. |

|

|||||||||||||||||||||||||||||

Right: Since the mirror must be locked in the UP position, you cannot view through the prism finder of the camera with this lens in place. A seperate viewfinder is therefore provided to outline the picture area. There are 4 types of dedicated viewfinders. The one shown on the left is the very rare Type 1 finder. The base of the finder is made of bakelite and is often broken. An undamaged unit is getting very hard to find. Do check carefully for signs of repair before you pay high price for a seemingly clean one. |

|||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||

Even among the Type 1 Finders, I notice there are small variations. The one on the left has glossy finish and the one on the right has mat finish. The letter "F"s on the two finders are of different font types and sizes too. |

|||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||

Shown to the right is the Type 1 finder (Left) in comparison to the more common Type 2 (Right). The Type 2 finder has a metal base. |

|||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||

The 676th lens from the start of the production and the 116th lens from the end of the production.

|

|||||||||||||||||||||||||||||||

The production of this lens started with serial numbers 220111 and ended at 227164. Among all the different variations, the most significant change happened from 225001. From that numbers onwards, the rear part of the lens was straightened on both sides, rather than just one, to give enough clearance for this lens to be used on Nikkormat bodies. (see photos below) |

|||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||

Lenses prior to 225001 cannot be mounted on Nikkormat bodies. |

Lens from 225001 was modified to be used on Nikkormat bodies. |

||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||

The early lenses have "PAT. PEND." engraved after "LENS MADE IN JAPAN". From around 2226xx, "PAT. PEND." no longer exist. It should be noted that the earliest lenses, probably the first 300 units, do NOT have either "LENS MADE IN JAPAN" or " PAT. PEND." on the lens barrel. |

|||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||

The Type 1 Nippon Kogaku Logo lens hood shown above has to be one of the rarest, if not THE rarest, lens hoods for the entire Nikon reflex system. Even the Type 2 hood (See picture below) for this lens is not easy to find these days. |

|||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||

|

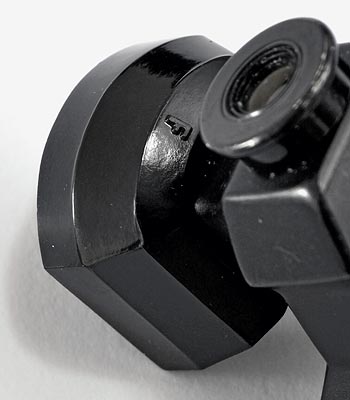

There is a slot at the back of the dedicated rear cap where you can mount the view finder. This cap is also used for 8mm f8, 7.5mm f5.6 and 10mm f5.6 fisheye lenses. However, you may notice an unusually large numbers of this cap associated with 2.1cm lens are damaged internally. Many could not even fit securely to the lens any more. I believe it has something to do with the unique design of this lens and the lack of understanding for the owners. In order to orientate the lens correctly when mounting, there is an additional prong at the back of the mount. The prong has to be moved to hide behind one of the bayonet tab before you can put the cap (or the camera body) on or off. Otherwise, the prong will simply get in the way, as shown in the two photos below. I suspect many owners found the cap stuck on the lens and did not understand what happened. They finally got frustrated and tried to break free the cap by force. As a result, they ended up with another broken rear cap! The replacement cap is often costly, that is IF you can find one in the first place! |

||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||

You can see from the left photo how the prong can potentially interfere with the mounting of this lens. The right photo shows the correct position of the prong to ensure a pain free operation when putting the rear cap on and off. This correct position can be achieved by lining up the white aperture/focus reference line with the black dot on the chrome rim of the lens. |

|||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||

| Because of the protuding rear part, this lens came with a dedicated leather case for storage rather than the standard display "bubble". | |||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||

Updated on 9 Jun 2023 |

|||||||||||||||||||||||||||||||